Solve Your German Stable Challenges with Expert Precision

From damp winters to strict welfare standards and social horse needs, ensure comfort, compliance, and durability—our tailored solutions deliver value and scalability for your bulk orders throughout Germany!

Overcome Your German Stable Challenges with Proven Solutions

Germany’s cold, wet climate, rigorous welfare standards, and equestrian traditions create distinct hurdles for horse owners and facility managers. Here’s how we address them with precision-engineered products:

Wet and Cold Climate Threatening Horse Health

- Problem: Frequent rain (up to 1000mm annually in western regions) and cold winters (-5°C to 5°C/23°F to 41°F) cause damp stables, mold growth, and respiratory issues—major concerns on Pferd-aktuell.de forums.

- Agitate: Dampness and cold lead to health issues like pneumonia, increasing vet costs and compromising horse welfare.

- Solution: Modular Group Stables feature insulated steel roofs (R-value 15, reduces condensation by 60%) and moisture-resistant HDPE panels, paired with adjustable 60cm x 30cm (2ft x 1ft) ventilation windows—tested to maintain dry interiors and ensure 4-6 air exchanges per hour, keeping horses healthy in Germany’s wet seasons.

Ensuring Compliance with German Welfare and Building Standards

- Problem: The German Animal Welfare Guidelines (BMEL 2009) recommend individual stables of at least (2 x horse shoulder height)² (e.g., 10.24m² for a 1.6m horse) and group stables with 100m² activity area plus 12m² lying area per horse—non-compliance risks legal issues or welfare penalties.

- Agitate: Non-compliance can lead to fines, project delays, and reputational damage for facilities.

- Solution: Luxury Swing Door Stables start at 3.6m x 3.6m (12.96m²), exceeding minimums, with 1.2m-wide (4ft) doors and 2.4m (8ft) ceilings, while Modular Group Stables offer 100m² activity zones and 12m² padded lying areas—includes compliance blueprints for state-specific building codes (e.g., Bavaria, NRW) to simplify bulk permitting.

Soggy Arenas Disrupting Training and Events

- Problem: Heavy rain in regions like the Rhineland turns arenas into mud, halting training and events—a frequent complaint in German equestrian circles.

- Agitate: Unusable arenas disrupt training schedules, cancel events, and lead to revenue loss.

- Solution: Arena Footing Grids (500x500mm HDPE) drain 200mm/hour, exceeding Germany’s average 80mm monthly rainfall, supporting 250 tonnes/m²—keeps surfaces firm and event-ready, from dressage in Munich to jumping in Hamburg.

High Maintenance Costs in Harsh Weather

- Problem: Wet and cold conditions rust metal and rot wood, driving up repair costs every 5-10 years—a top issue for German rural stables, per FN feedback.

- Agitate: High maintenance costs erode profits and increase operational burdens for facility managers.

- Solution: Rubber Mats (1830x1220mm, 17mm thick) and Steel Fences (1.2m-1.8m high, galvanized) resist moisture and corrosion, reducing cleaning time by 50% and lasting 15-20 years—cuts labor and replacement costs for bulk farm installs.

Meeting Social Interaction Needs for Horse Welfare

- Problem: Isolated stalls increase stress and behavioral issues, against BMEL welfare guidelines favoring social contact—German owners emphasize this on forums.

- Agitate: Stress leads to behavioral issues and health problems, increasing management challenges.

- Solution: Sliding Doors with 1.2m-high low partitions and optional 60cm x 30cm (2ft x 1ft) steel-grilled windows allow horses to see and interact, reducing stress—reflects Germany’s preference for group or open stable designs.

Scaling Up for Diverse Farm Sizes

- Problem: Farms range from small holdings to large estates, needing flexible, quick-to-install setups—rigid designs delay growth, per Wolfsystem insights.

- Agitate: Inflexible designs slow expansion, increasing costs and limiting farm growth potential.

- Solution: Modular Group Stables (100m² base, expandable) and Luxury Swing Door Stables (3.6m x 3.6m base) with bolt-on steel panels install in days—scalable from 5 to 50 units, ideal for Germany’s varied farm landscapes.

DB Stable: Premium Custom Internal Horse Stables

At DB Stable, we redefine equestrian excellence with our custom-built internal horse stables, engineered to provide unmatched quality, safety, and functionality. With decades of experience serving markets in the Germany, and beyond, our stables are designed for both competitive and leisure facilities, ensuring your horses enjoy a secure and comfortable environment.

Key Features:

• High-Quality Construction – Built with robust materials for longevity, ensuring optimal ventilation and ease of access.

• Range of Sizes – Standard options such as 10’x10′, 12’x12′, 14’x14′, and 16’x16′; custom dimensions available.

• Customisation Options – Choose from swinging, sliding, or split pony doors and select infills from recycled plastic (black, brown, grey) or elegant hardwood.

• Comprehensive Solutions – Along with internal stables, we offer external stabling, horse panels, tie-up systems, and more to suit all equestrian needs.

Choose DB Stable for reliable, tailor-made stabling solutions designed to keep your horses safe and comfortable.

DB Stable – Premium Stable Manufacturers

Based in Anping, China, DB Stable supplies high-quality, steel-framed horse stables to the Germany, Europe, and beyond. We specialize in both internal and external stables with modular designs that ensure durability and safety.

Key Features:

• Steel-Framed Stables – Internal and external options with recycled plastic boarding for longevity.

• Versatile Designs – Custom stable doors, metal-framed buildings, mobile shelters, and partitions.

• Comprehensive Accessories – Horse mats, horse arena, horse-tie-up, horse window, horse door, etc.

• Cost-Effective Customization – Expert design meets competitive pricing and tailored solutions.

• Proven Quality – Client references and on-site visits available to showcase our craftsmanship.

Based in Anping, China, DB Stable supplies high-quality, steel-framed horse stables to the UK, Europe, and beyond. We specialize in both internal and external stables with modular designs that ensure durability and safety.

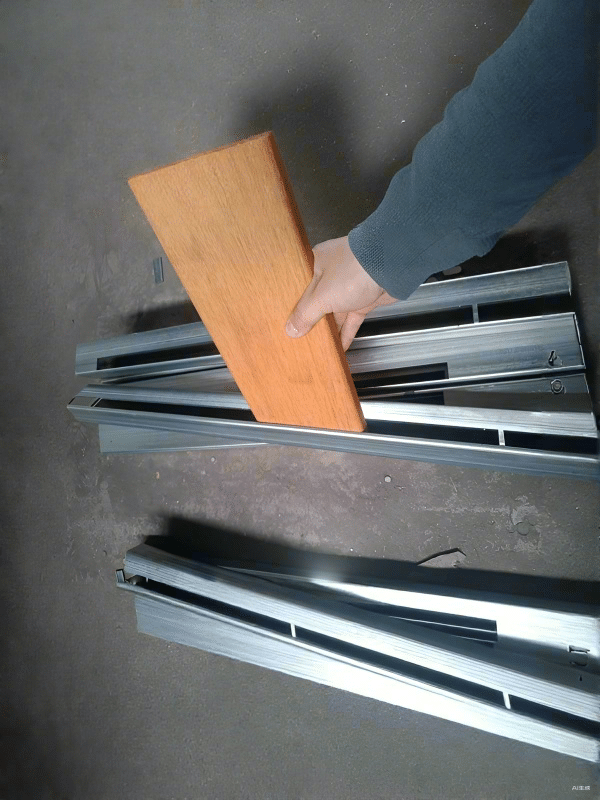

Standard Internal Stables Frames

Engineered for strength and flexibility, our standard internal stables are built with fully welded box channel and angle steel profiles for superior durability and easy installation on any surface.

• Fully Welded Frames – Enhanced strength versus bolted construction, with top and removable bottom bars to suit rubber mat installations or clear door access.

• Hybrid Range Option – Optional 50x50mm or 40x60mm sqaure tube as frames with floor fixing plates; eliminates the need for top or bottom bars, ideal for curved fronts.

• Robust Boarding Support – Internal channels welded for secure tongue and groove boarding, with additional framing on all sides for maximum stability.

• Premium Finish – All frames are galvanized to ISO 1461 standards, with optional coloured powder coating.

DB Stable – Premium Stable Boarding Options

Enhance your stable’s look, strength, and durability with our range of high-quality boarding options designed for our standard internal stables:

• Choice of Materials – Select from HDPE panel, recycled plastic, or our innovative resin woven bamboo.

• Tongue & Groove Precision – Standard T&G boards are 20mm, 30mm, 32mm thick and designed to fit seamlessly into our 40mm or 50mm channels. Custom cut to your stable’s dimensions, ensuring a perfect fit even if you’re installing them yourself.

• Resin Woven Bamboo Excellence – Experience the next level of stable boarding. Our bamboo boards are 20m/ 32mm thick and 140mm wide, crafted by stripping, weaving, and compacting bamboo shoots with resin to achieve twice the density of traditional hardwood. A lacquer coating provides UV protection and seals against water ingress, offering unmatched durability and minimal maintenance.

DB Stable – Swivel Mangers & Hay Feeders

- Swivel Mangers: Attach to the lower stable panels, pivot around a central point, and secure with a drop bolt for inside or outside positioning. Made from toughened plastic with a central drain for easy cleaning.

- Removable Stainless Steel Troughs: Robust, corrosion-resistant, and simple to clean for a hygienic feeding area.

- Fixed Stainless Steel Troughs: Permanently attach to the stable for a dedicated feeding space.

- Space-Saving Corner Manager: Aluminum-supported plastic unit with a 31-liter capacity, designed to optimize space and simplify maintenance.

- Hay Feeder: Aluominium or Stainless Steel Material.

DB Stable – Horse Stable Doors

Swinging Doors:

- Standard: 1220mm wide, 1305mm high; premium option at 1230mm by 1355mm.

- Features: Steel-framed boarding with optional anti-chew plates.

- Hardware: High-quality shoot bolts, galvanized kick-over latches, and selectable hinged top styles (anti-weave, fully grilled, fully boarded).

- Options: Lower pony doors with extension available.

Sliding Doors:

- Mechanism: Top-grade rollers with flip-over latches (spring-loaded option available). •

- Customizable Top: Standard open-top; can be upgraded to anti-weave, fully grilled, or fully boarded. • Adaptability: Suitable fixings for wooden or blockwork stables.

DB Stable – Stand Alone Horse Tie-Up Posts

- Heavy-Duty Design: 89mm round posts with a robust 200mm square base plate that bolt directly to concrete, perfect for tack-up, wash-down, and solarium areas.

- HDPE Panel: 20mm thick panel assembled.

- Safety & Ease: Recessed tie rings integrated into the steel construction enhance safety and simplify use.

- Custom Fixings: All required fixings are supplied to suit your installation needs. Securely mount posts to various surfaces using slotted L brackets, thunder bolts for brick or concrete, or coach bolts/screws for wood.

Comprehensive Solutions for German Equestrian Demands

Modular Group Stable

Addresses: Social interaction and scalability.

Details: 100m² activity area, 12m² lying area per horse, galvanized steel frame, insulated roof (R-15), HDPE panels, 2.4m-3m (8ft-10ft) ceiling, 1.2m-wide (4ft) sliding doors, 60cm x 30cm (2ft x 1ft) ventilation windows, wind-resistant to 120km/h, 20-year lifespan.

Benefits: Meets group welfare needs, scales for farms, ensures comfort—ideal for bulk rural upgrades in Germany.

Luxury Swing Door Stable

Addresses: Wet climate and compliance.

Details: 3.6m x 3.6m (11.8ft x 11.8ft) base, expandable to 4m x 4m (13.1ft x 13.1ft), bamboo or galvanized steel, 1.2m-wide (4ft) swing door, 60cm x 30cm (2ft x 1ft) ventilation gap, 2.4m (8ft) ceiling, moisture-resistant, 20-year lifespan.

Benefits: Exceeds 10.24m² welfare minimums, keeps interiors dry—perfect for individual German stables.

Horse Riding Arena

Addresses: Soggy arenas.

Details: 500x500mm HDPE grids, 40mm depth, drains 200mm/hour, supports 250 tonnes/m², UV-resistant, stackable for bulk shipping, 15-year lifespan in wet conditions.

Benefits: Drains rain quickly, ensures firm surfaces—supports year-round training and events in Germany, such as the CHIO Aachen.

Heavy Duty Rubber Mats

Addresses: Maintenance and dampness.

Details: 1830x1220mm, 17mm thick, 40kg weight, anti-slip textured surface, moisture-resistant rubber compound, supports 1000kg horse load, hose-cleanable, 10-year durability in wet conditions.

Benefits: Reduces dampness and cleaning by 50%, protects floors—saves labor costs for German farms.

Horse Fence

Addresses: Wear and maintenance.

Details: 1.2m-1.8m high, 100mm spacing, hot-dip galvanized steel, 3mm wire thickness, supports 120km/h winds, modular design for 50+ panel installs, 15-20 year lifespan, optional UV-resistant coating.

Benefits: Resists rust and wet weather, scales for large paddocks—cuts maintenance for German farms.

Horse Show Jumps

Addresses: Ventilation, dampness, and social interaction.

Details: 1.2m x 2.2m, adjustable galvanized steel or aluminum, UV-coated finish, 60cm x 30cm (2ft x 1ft) grilled window option, rust-proof tracks, wind-resistant to 120km/h, supports 1000kg load, space-saving sliding design with low-partition compatibility.

Benefits: Boosts airflow, reduces dampness, enhances social needs—perfect for German welfare standards.

Comprehensive Technical Support for German Projects

German Stable Design Guide:

Includes layouts for individual stables (3.6m x 3.6m/12.96m² minimum) and group stables (100m² activity area + 12m² lying area per horse), ceiling heights of 2.4m-3m (8ft-10ft), 1.2m-wide (4ft) doors, ventilation specs (4-6 air exchanges/hour per BMEL), drainage slopes (1:60 gradient), and material durability charts (steel vs. HDPE vs. bamboo in wet conditions).

Wet Climate Maintenance Manual:

Care instructions for wet winters (rust checks every 6 months), damp regions (mat hosing weekly), and mild summers (UV checks annually)—extends lifespan to 20 years with tips for 1000mm annual rainfall zones.

Bulk Order Blueprint:

Detailed plans for 10-stable farm setups or 50-fence paddock layouts, including spacing (3m post intervals), wind load calculations (120km/h), drainage designs, and installation timelines (e.g., 5 days for 10 stables with a 3-person crew).

Precision Manufacturing for the German Market

Our China-based factory leverages advanced technology and customization to meet German B2B demands with exceptional quality. With over a decade of expertise, DB Stable’s factory produces stables, arenas, fences, and barn windows for German clients:

Custom Production:

Crafting R-15 insulated Modular Group Stables for Bavaria’s cold, moisture-resistant Luxury Swing Door Stables for Rhineland’s dampness, and BMEL-compliant arenas for diverse needs.

High Output:

Manufacturing 500+ units monthly using automated welding, cutting, and coating lines, ensuring timely bulk order delivery.

Premium Materials:

Using galvanized steel (20-year rust resistance), UV-resistant HDPE (15-year lifespan), and sustainable bamboo for durability and aesthetics.

Rigorous Testing:

Multi-stage testing for load (1000kg), weather resistance (-5°C cold to 1000mm rainfall), and safety, meeting ISO 9001, CE, and BMEL standards.

Efficient Processes:

Optimized production reduces costs and delivery times, providing updates (videos, photos) for German farms and training centers.

Maximize Value for Your German Clients with Bulk Solutions

Compliance Across Regions:

Pre-engineered stables meet BMEL welfare guidelines (10.24m² individual, 100m² + 12m² group), with customizable add-ons for state building codes (e.g., wind resistance in Schleswig-Holstein, fire safety in Bavaria)—includes compliance docs to speed permitting for bulk orders.

Cost Savings with Scale:

Tiered discounts: 5% off for 10 stables (e.g., €600 savings on a €12,000 order), 10% off for 30 jumps, 15% off for 50 fences (e.g., €1,800 savings on a €12,000 order)—keeps large projects profitable.

Fast, Flexible Delivery:

Shipping from China in 4-6 weeks with real-time tracking, expedited options (2-4 weeks) for events like the CHIO Aachen—German warehouses in Hamburg and Frankfurt cut lead times to 1-2 weeks for urgent orders.

Expert Danish Support:

Dedicated German account managers provide climate-specific advice (Rhineland dampness, Bavarian cold), welfare code guidance, and virtual consultations for orders over 20 units—ensures project success from Hamburg to Munich.

Detailed Answers to German Equestrian Needs

How do you keep German stables dry and healthy in wet, cold weather?

Modular Group Stables with insulated steel roofs (R-15, reduces condensation by 60%) and HDPE panels dry interiors under 1000mm annual rain—ventilation windows ensure 4-6 air exchanges/hour (BMEL standard), cutting health risks for horses.

How do your products ensure compliance with German welfare standards?

Individual stables at 3.6m x 3.6m (12.96m²) exceed 10.24m² minimums, group stables offer 100m² activity + 12m² lying areas per horse—includes blueprints to simplify bulk permitting.

How do you fix soggy arenas for German training and events?

Arena Footing Grids drain 200mm/hour, exceeding Germany’s 80mm monthly rainfall—supports 250 tonnes/m², ensuring year-round usability for events like the CHIO Aachen.

What’s the minimum order for cost-effective large German farm projects?

Starts at 10 stables, 30 jumps, or 50 fences, with discounts up to 15%—we’ll tailor a budget-friendly bulk plan for your clients’ scope (e.g., 20 stables for a farm).

How durable are these solutions in Germany’s climate?

Galvanized steel resists rust and 120km/h winds, HDPE withstands dampness—built for 15-20 years. Includes a wet climate care manual (e.g., rust checks in winter) for reliability.

What are the delivery times for Germany?

Global delivery in 4-6 weeks, expedited at 2-4 weeks; Hamburg and Frankfurt warehouses offer 1-2 week delivery with tracking. Contact us for rush options.

Get in Touch

Boost your equestrian facility with our expertly crafted stables, fences, and arenas. With over 10 years of manufacturing experience, we specialize in enhancing your inventory with durable, compliant products tailored for global markets. Contact us to explore how we can meet your business needs.

- Over a decade of proven expertise in equestrian product manufacturing.

- Focused on supporting your business with scalable production and customization capabilities.

- Serving clients across 9 countries, from Australia to Poland.

- Fast, efficient responses to inquiries, typically within 24 hours.

- Customized designs to meet specific regional and facility requirements.