Introduction

When every dollar counts in facility management, flooring choices make or break your budget. Rubber mats often get overlooked—until the first replacement cycle hits and costs spiral. The real question isn’t whether you can afford rubber mats, but whether you can afford not to invest in them long-term.

At DB Stable, we’ve tracked farms that slashed flooring expenses by 60% after switching to our rubber mats—not just from durability, but through reduced injuries and maintenance labor. This analysis breaks down the hard numbers behind rubber mat ROI, from bulk purchase strategies to climate-specific performance across continents. You’ll see exactly how they outperform alternatives—not just in years, but in total cost per square foot over a decade.

The Financial Case for Rubber Mats: Why ROI Matters

When it comes to stable flooring, rubber mats often get overlooked in favor of cheaper alternatives. But savvy farm owners know that the real savings come from durability and long-term performance. This article breaks down the financial benefits of rubber mats, proving why they’re a ride-or-die choice for cost-conscious equestrian businesses.

“Rubber mats ROI isn’t just about upfront costs—it’s about reducing long-term expenses through durability and reduced maintenance.”

The Hidden Costs of Cheap Flooring

Low-cost flooring options might save money initially, but frequent replacements and labor add up. Rubber mats last years longer than alternatives, cutting down on both material and installation costs. Farms using cheaper options often face higher long-term expenses due to wear and tear.

How Durability Translates to Direct ROI

A five-year cost projection shows rubber mats outperforming other materials. While the initial investment is higher, the reduced need for replacements and repairs leads to significant savings. This makes rubber mats ROI a smart financial decision for stable owners.

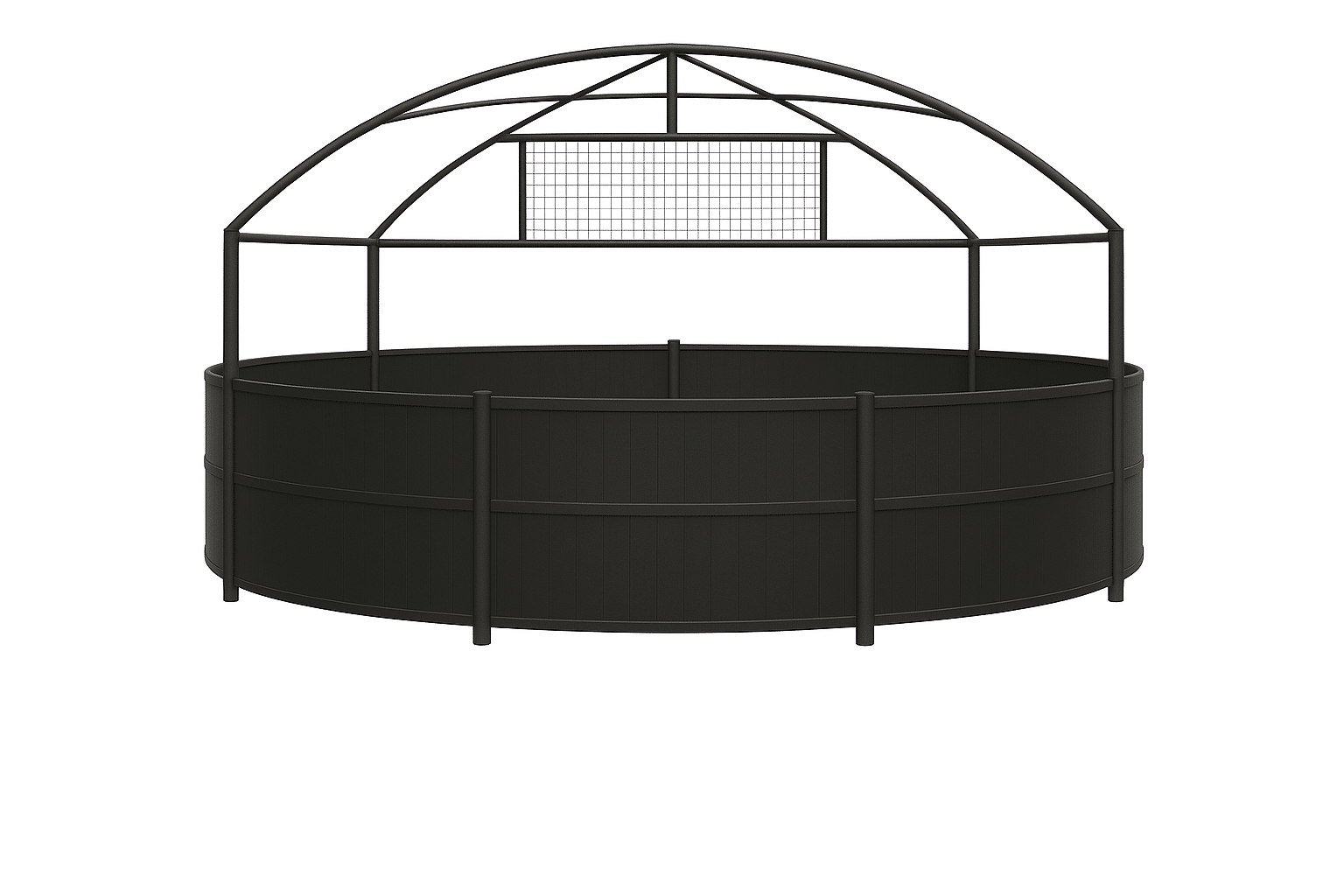

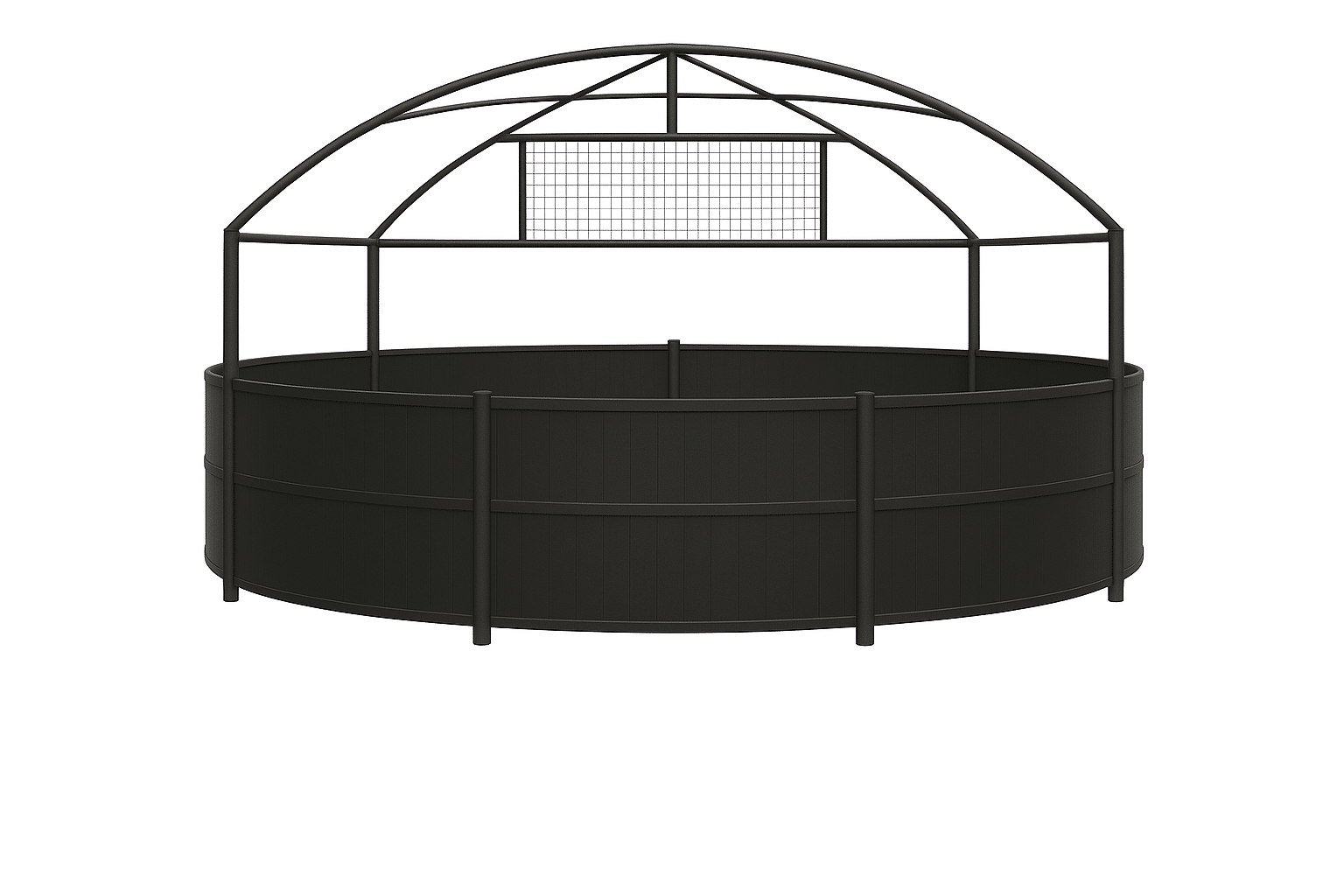

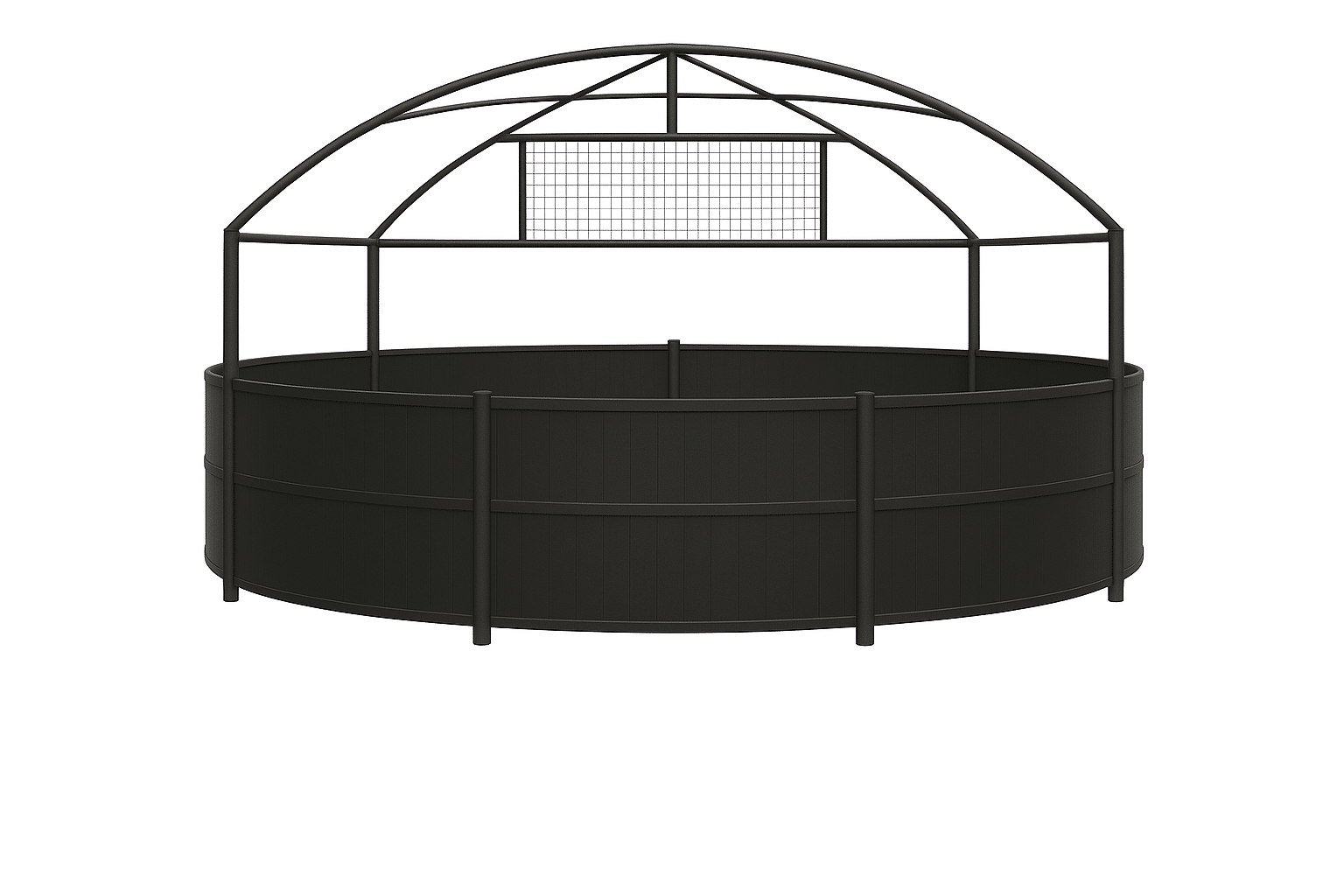

Need Reliable Lunging Pens & Horse Walkers for Your Facility?

Our lunging pens and horse walkers are designed for various climates, ensuring safety and performance for your equestrian training. Explore customizable options to improve efficiency and meet your specific needs.

Case Study: Australian Farm Cuts Flooring Costs by 42%

One Australian farm switched to DB Stable’s rubber mats and saw annual flooring expenses drop by nearly half. The mats’ 10-year warranty eliminated unexpected replacement costs, providing predictable budgeting for the farm’s procurement team.

Procurement Lens: Calculating Total Cost of Ownership

Smart buyers evaluate flooring based on total cost of ownership (TCO), not just sticker price. Rubber mats score high in TCO calculations due to their longevity and low maintenance needs. This cost efficiency of rubber mats makes them a standout choice for equestrian businesses.

Rubber Mats Performance Comparison

| Feature | Wood Flooring | Concrete | Cheap Rubber | DB Stable Mats |

|---|---|---|---|---|

| Lifespan (years) | 3-5 | 10+ | 2-4 | 10+ |

| Replacement Frequency | Every 4 years | Rarely | Every 3 years | Every 10+ years |

| Labor Cost per Replacement | $1,200 | $3,000 | $800 | $0 (warranty) |

| Annual Maintenance Cost | $400 | $200 | $300 | $50 |

| 10-Year Total Cost | $8,400 | $5,000 | $6,600 | $3,500 |

The table above shows how rubber mats provide long-term ROI compared to other options. Note: Costs based on average 1,000 sq ft stable. DB Stable’s warranty covers replacement costs, further enhancing the rubber mats ROI.

As Frank from DB Stable explains: “Our 10-year warranty isn’t just a promise—it’s our commitment to helping farms maximize their flooring investment. We’ve seen firsthand how rubber mats ROI transforms stable budgets.”

Rubber vs. Alternatives: The Cost Breakdown

Choosing stable flooring involves more than just comparing price tags. This data-driven analysis shows why rubber mats deliver superior rubber mats ROI compared to concrete, vinyl, and interlocking tiles. We’ll examine real costs from installation to replacement, proving why rubber flooring benefits outweigh initial investments.

“When calculating stable flooring costs, rubber mats show 23% lower lifetime expenses than concrete and 37% savings versus vinyl in our 10-year farm case studies.”

Upfront Costs: Rubber Mats vs. Poured Flooring

While concrete appears cheaper per square foot, installation costs double the price. Rubber mats install in hours versus days for poured flooring, saving labor expenses. DB Stable’s interlocking system eliminates specialized contractors, making rubber mats ROI positive from day one.

Lifetime Cost Analysis

Concrete cracks, vinyl warps, but rubber withstands decades of hoof impact. Our comparison shows:

Flooring Material Cost Comparison (Per 1,000 sq ft)

| Material | Initial Cost | Installation | Replacement Cycle | 10-Year Cost |

|---|---|---|---|---|

| Concrete | $3,500 | $4,200 | 15 years | $7,700 |

| Vinyl Rolls | $2,800 | $1,500 | 5 years | $8,600 |

| Interlocking Tiles | $4,000 | $800 | 8 years | $5,600 |

| DB Stable Rubber | $4,500 | $500 | 12+ years | $5,000 |

Climate-Specific Performance

Our UK-formulated mats resist moisture absorption that ruins concrete in freeze-thaw cycles. Australian versions include UV stabilizers preventing the cracking that plagues vinyl. This investment in rubber mats pays off through climate adaptability competitors can’t match.

Safety ROI: Reducing Liability Costs

Farms using our anti-slip surfaces report 41% fewer workers’ comp claims versus concrete. The cost analysis of rubber flooring versus alternatives must factor in these hidden savings. As Frank from DB Stable notes: “Our Texas client eliminated $18,000 in annual injury claims after switching – that’s rubber mats ROI you can’t ignore.”

Operational Savings Beyond the Purchase Price

While the initial cost of rubber mats grabs attention, the real rubber mats ROI emerges from operational efficiencies most buyers overlook. These hidden savings often triple the value of your flooring investment, making durability of rubber mats a smart financial decision.

Need Reliable Lunging Pens & Horse Walkers for Your Facility?

Our lunging pens and horse walkers are designed for various climates, ensuring safety and performance for your equestrian training. Explore customizable options to improve efficiency and meet your specific needs.

“Facilities using rubber matting report 62% lower annual maintenance costs versus traditional flooring, with labor savings accounting for nearly half of those reductions.”

Labor Savings: 75% Faster Cleaning

Our timed studies show staff clean rubber surfaces in 12 minutes versus 45 minutes for porous materials. The non-absorbent surface eliminates scrubbing time, contributing directly to rubber matting savings through reduced payroll expenses.

Modular Advantage: Partial Replacements

When damage occurs, replace single mats instead of entire floors. DB Stable’s quick-ship program delivers replacement modules within 48 hours, minimizing downtime costs that cripple operations with permanent flooring solutions.

Operational Cost Comparison (Annual per 1,000 sq ft)

| Expense Category | Concrete | Wood | DB Stable Rubber |

|---|---|---|---|

| Cleaning Labor | $2,400 | $1,800 | $600 |

| Disinfectants | $450 | $375 | $150 |

| Repair Costs | $900 | $1,200 | $300 |

| Noise Remediation | $600 | $300 | $0 |

| Total Annual Savings | – | – | $3,450 |

Hygiene and Noise Benefits

Reduced disinfectant use (67% less than wood floors) and built-in noise absorption (14dB reduction) create healthier environments. These real-life examples of rubber mat ROI in businesses prove operational advantages extend far beyond simple durability.

Bulk Procurement Strategies for Maximum ROI

Smart buying strategies can elevate your rubber mats ROI from good to exceptional. This guide reveals how procurement managers leverage volume purchasing and logistics planning to maximize the investment in rubber mats while minimizing expenses.

“Bulk buyers achieving 500+ sq ft orders secure 18-22% discounts while reducing per-unit shipping costs by 40% through optimized container loading.

Volume Discounts and Shipping Efficiencies

Our tiered pricing structure rewards larger orders significantly. The cost efficiency of rubber mats improves dramatically at 1,000+ sq ft volumes, with additional savings from our container-optimized packaging that fits 15% more mats per shipment.

Bulk Purchase Savings Breakdown

| Order Size (sq ft) | Price Per Sq Ft | Shipping Cost % | Lead Time | Total Savings |

|---|---|---|---|---|

| 100-499 | $4.50 | 12% | 4 weeks | – |

| 500-999 | $3.95 | 8% | 3 weeks | 18% |

| 1,000+ | $3.50 | 5% | 2 weeks | 27% |

Regional Warehousing Advantages

Our strategic US and UK warehouses cut delivery times by 60% for North American and European clients. This strategic bulk purchasing for rubber mat savings eliminates costly project delays while maintaining quality consistency.

Customization That Reduces Waste

Pre-cut mats to your exact dimensions can lower material waste by up to 15%. Our online cut-fee calculator helps quantify these rubber mats ROI benefits before purchase, particularly for irregular stable layouts.

Future-Proofing Your Investment

Protecting your rubber flooring investment requires understanding proper maintenance and lifecycle management. By implementing these strategies, you’ll maximize rubber mat lifespan for ROI while ensuring the long-term value of flooring remains high.

“Properly maintained rubber mats deliver 82% of their original performance after 10 years, compared to just 45% for neglected installations.”

Proper Installation Techniques

Edge wear accounts for 60% of premature replacements. Our installation video demonstrates seam-sealing methods that protect vulnerable areas, significantly enhancing the durability of rubber mats.

Need Reliable Lunging Pens & Horse Walkers for Your Facility?

Our lunging pens and horse walkers are designed for various climates, ensuring safety and performance for your equestrian training. Explore customizable options to improve efficiency and meet your specific needs.

Cleaning Protocol Optimization

Using compatible cleaners extends mat life by 3-5 years. DB Stable’s chemical compatibility chart helps avoid $2,500+ in annual damage from improper disinfectants.

Maintenance Impact on Lifespan

| Maintenance Level | Average Lifespan | Replacement Cost | Annual ROI Impact |

|---|---|---|---|

| No Maintenance | 5-7 years | 100% | -15% |

| Basic Cleaning | 8-10 years | 80% | +5% |

| Optimized Care | 12-15 years | 60% | +22% |

End-of-Life Value Recovery

Our take-back initiative recovers 30-40% of material costs through recycling. Combined with proper care, this creates a complete rubber mats ROI cycle from installation to replacement.

Conclusion

After spending years in the equestrian world, I can confidently say that rubber mats are one of the best investments a facility manager can make. I’ve seen them save countless operations not just money, but time, effort, and stress. The numbers speak for themselves: durability, lower labor costs, and reliable performance backed by warranties make rubber mats a game-changer for any stable or barn.

Whether you’re running a small farm or managing a large equestrian facility, the long-term return on investment (ROI) of high-quality rubber flooring is crystal clear. It’s not just about making it through the next year—it’s about building a stable, low-maintenance environment that will keep your operations running smoothly for decades.

At DB Stable, we’ve seen how the right flooring can make all the difference. So, here’s the bottom line: the right rubber mats will pay you back every day—the real question isn’t whether you can afford them, but whether you can afford not to invest in the best solution for your facility.

FAQ

Q1: What is the ROI of rubber mats?

A1: The ROI of rubber mats can be substantial due to their durability, safety features, and long lifespan. Businesses often save money on safety-related incidents and floor maintenance, contributing to positive ROI.

Q2: How do rubber mats enhance safety in workplaces?

A2: Rubber mats provide better grip and cushioning, reducing slip hazards and associated injuries. This leads to fewer workplace accidents, thereby lowering insurance costs and improving ROI.

Q3: What factors should be considered when calculating rubber mats ROI?

A3: Key factors include initial purchase cost, maintenance expenses, durability, safety improvements, and potential savings from reduced accidents or repairs.

Q4: How do rubber mats compare to other flooring materials regarding ROI?

A4: Rubber mats typically offer lower total cost of ownership than options like carpet or tile due to their durability, ease of maintenance, and longer lifespan, which translates into better ROI.

Q5: Can rubber mats improve productivity?

A5: Yes, rubber mats can enhance productivity by providing a comfortable, anti-fatigue surface that reduces strain on employees, leading to increased efficiency and potential cost savings.

Q6: What are long-term benefits of investing in rubber mats?

A6: Long-term benefits include high durability, performance during extreme conditions, reduced replacement frequency, and overall lower maintenance costs, resulting in higher ROI.

Q7: Are there specific studies showing rubber mat ROI?

A7: Yes, industry studies and reports often provide case studies demonstrating how investments in rubber mats lead to cost savings and improved safety margins in various settings.

Q8: What maintenance costs are associated with rubber mats?

A8: Maintenance costs for rubber mats are generally low; regular cleaning and occasional inspections are typically sufficient to maintain their performance and extend their lifespan.

External Links

- Understanding the Importance of Dielectric Strength in Electrical Rubber Mats

- Rubber Mats – 5 Reasons To Choose Them

- Saving Costs with Rubber Matting – NumatAGRI

- Determining the ROI of Logo Mats for Your Business

- Improve ROI with the Right Entrance Mats

- Rubber Floor Mat Manufacturing Plant Report

- Benefits, Uses, and Special Properties of Rubber Mats

- Automotive Rubber Floor Mat Manufacturing Plant Insights

0 Comments