by Frank | Jan 25, 2026 | Blog

The promise of labor savings from prefab horse stall kits is lost when projects rely on on-site welding. While a weld-it-yourself kit appears cheaper on the initial invoice, the hidden costs of specialized site labor and inevitable rust repairs can destroy a...

by Frank | Jan 25, 2026 | Blog

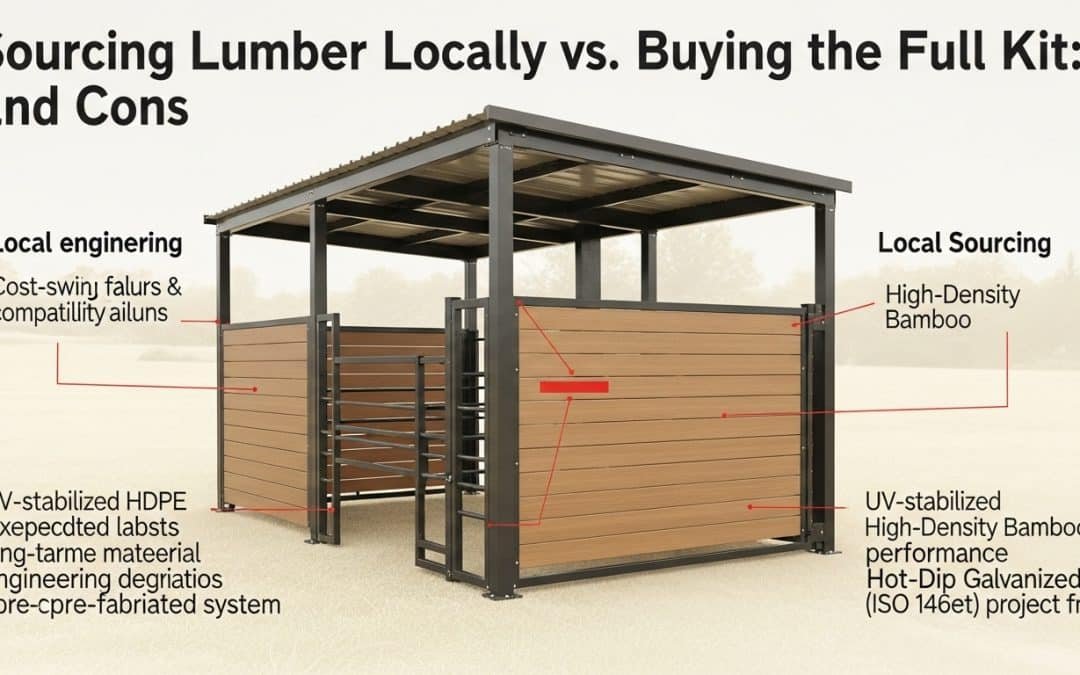

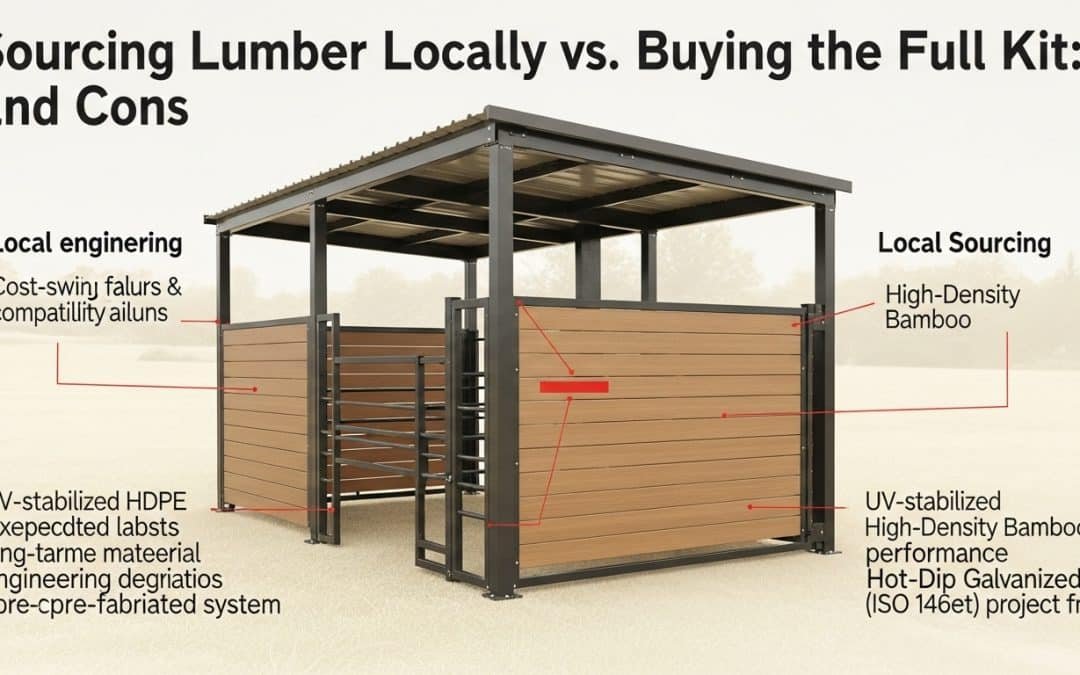

Sourcing stall kit lumber separately from the steel frame appears to be a cost-saving measure, but it often creates compatibility failures and project delays. This sourcing mistake can erase profit margins through unexpected labor costs and long-term material...

by Frank | Jan 25, 2026 | Blog

Mistakes when installing horse stalls using residential building standards lead directly to project callbacks and liability. Even veteran general contractors often underestimate the engineering demands of an equine environment, resulting in structural failures that...

by Frank | Jan 25, 2026 | Blog

Specifying the correct cold climate winter horse stalls is the primary defense against catastrophic material failure. Using standard structural steel in sub-zero temperatures invites brittle fractures and warped panels, leading directly to costly warranty claims and...

by Frank | Jan 25, 2026 | Blog

Sourcing the right C2-6: Safety Featuressafe horse stall kit is the primary defense against the hidden liabilities found in standard designs. Many low-cost kits use wide bar spacing and thin-gauge steel, creating entrapment hazards that lead directly to catastrophic...

by Frank | Jan 25, 2026 | Blog

Specifying the correct Retrofit stall kits for existing barns is the difference between a profitable project and a liability nightmare. Rigid, pre-welded systems are incompatible with the structural quirks of old buildings, forcing expensive on-site fabrication that...